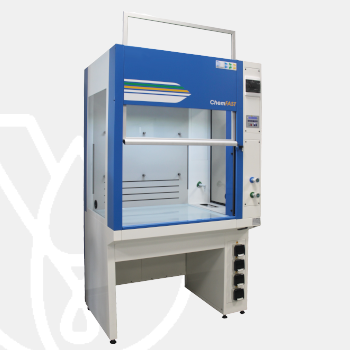

ChemFAST Classic

ChemFAST Classic are total exhaust chemical fume cupboards working at Constant Air Volume technology (CAV). The inflow velocity can be adjusted from 0,3 to 0,7 m/sec, both during the installation and ordinary maintenance; this feature makes it possible to choose the safest velocities for the removal of contaminants.

ChemFAST Classic complies with the requirements of the EN 14175 part 1, 2, 3 “Machinery Directive 2006/42/ CE” standards designed to guarantee operator and environmental safety with a ventilation outside the building without internal recirculation.

ChemFAST Classic assures flexibility, safety and user friendliness and represents the ideal solution for chemical labs thanks to a combination of high standards of protection for the operator with a reduced air consumption. It prevents the risk of chemical agents, vapors and aerosols contamination during normal routine laboratory work.

Customized option for handling strong acids at high temperatures: ChemFAST Classic with Ceramic work surface, internal coating with ceramic panels in Monolite IPERGRES which does not affect the aeraulic performance.

Customized option for handling hydrofluoric acid: ChemFAST Classic with Polypropylene work surface, internal coating with Polypropylene panels which do not affect the aeraulic performance.

The operation of the ChemFAST Classic is based on the principle of a constant flow vented system: the air is taken in from the outside, through the front opening, then it passes to the level of the worktop from where the contaminant is removed through the above-mentioned flow of air towards the top of the hood.

The air is taken by a remote fan, usually located in another room and connected to the hood by means of an extraction system formed by several meters of pipes.

The front speeds will therefore be variable between 0.3-0.5-0.7 m/s and the operating flow rates will consequently be constant and connected to this selection.

More energy savings. The frontal reach and speed of ChemFAST Classic can be calibrated, during installation, on three different levels 0.3-0.5-0.7 m/s in order to find a favorable compromise between air-conditioning consumption and the most difficult pollutant removal rates.

More precision. A real vane anemometer supplies the most accurate information on the air velocity within the exhaust circuit.

Optimized energy consumption and reduced CO2 emissions in environment thanks to Controlling System: the microprocessor uses the latest innovative methods of integrated management of all the main ventilation functions, it self-regulates all the main components of the system, compensating the pressure drop and restoring the balance of power.

Ergonomics. Plenty of space beneath the cabinet for a ventilated safety box for the storage of reagents and opportunity to work sitting on a chair.

Easy connection to an existing engine, considering also the need to install filters groups. Basically they can work independently using an existing ducting system (after evaluation of the total air flow rates).

Silent operation: the plenum, the hood structures and the software itself, are designed to provide the optimal air management features, ensure silent operation of this safety device, with sound pressure levels recorded well below the parameters specified in the current European standard EN 14175 for chemical fume Hoods.

Antibacterial coating: Dupont ™ ALESTA® anti-bacterial is able to prevent microbial contamination of surfaces inhibiting in that way the long-term growth of surface contamination.

Compartments under the hood. It is possible to install safety storage cabinets under the hood, since the central space is not taken up by something else, or you can opt for a different solution and have classic or vented cabinets with wheels that are easy to open and close.

Electrical, hydraulic and gas utilities are concentrated on one shoulder of the hood. The electric utilities can be placed inside the hood, as we offer IP66 plug-in sockets, increasing the capacity from 4 sockets to 8 sockets (4 internal and 4 external). Up to 8 controls or alternatively 4 pressure reducers can be installed.

Automatic safety fittings for gas and vacuum and standard electrical sockets in each model and for each size. Internal and external IP 66 protection.

Lighting: the positioning and sizing of the side safety windows provide the highest level of brightness to the work area and create an ideal lighting system.

FILTRATIONS (Optional)

ChemFAST Classic hoods do not have filters as standard, but can be supplied with external filtering groups downstream of the ducted system.

The filters provided can be charcoal or HEPA depending on the type of application that is carried out inside the hood.

Extract fan. (optional)

FILTRATIONS (Optional)

ChemFAST Classic hoods do not have the filters as standard, but can be supplied with external filtering groups downstream of the ducted system.

The filters provided can be charcoal or HEPA depending on the type of application that is carried out inside the hood.

Extract fan. (Optional)