The SB10-X is an orbital shaken benchtop bioreactor system for the cultivation of human, mammalian and plant cells in a single-use bag. It consists of six modules (excluding the bag) and has a working volume from 4 litres up to 12 litres.

The SB10-X can be used in research, process development or as a pilot scale bioreactor.

Performance characteristics

- Cultivation of human, mammalian and plant cells

- Fast, simple set up

- Easy scale-up

- Online measurement and control of pH and DO

- Three different types of single-use bags available

Orbital shaken benchtop bioreactor for single-use bags

The SB10-X is an orbital shaken benchtop bioreactor system for the cultivation of human, mammalian and plant cells in a single-use bag. It consists of six modules (excluding the bag) and has a working volume from 4 litres up to 12 litres.

The SB10-X can be used in research, process development or as a pilot scale bioreactor.

Performance characteristics

- Cultivation of human, mammalian and plant cells

- Fast, simple set up

- Easy scale-up

- Online measurement and control of pH and DO

- Three different types of single-use bags available

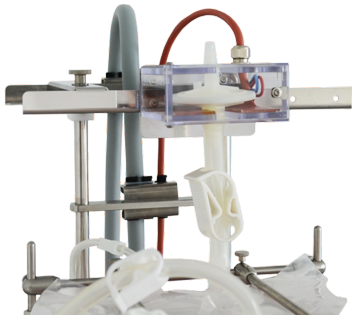

Bag

Single-use bag for a fast and simple set up

The cylindrical vessel accepts a single-use 3D bag. This bag requires no additional mixing device, enables quick set up times and eliminates elaborate cleaning and sterilising procedures. Various ports are incorporated to allow feeding, inoculation, harvesting and sampling. The standard bag has built-in optical sensors for pH/DO allowing online measurement and control of pH and DO in the medium. Two other bag types are available: a basic single-use bag with no optical sensors and a perfusion bag for ATF and TFF perfusion.

Orbital motion

Orbital motion

The orbital motion of the SB10-X ensures efficient liquid mixing. It facilitates high oxygen transfer rates with low shear forces. Mechanical stress on the cells is reduced thanks to bubble-free surface gassing with almost no frothing. This motion is particularly suitable for microcarrier cultivation. The SB10-X uses the unique Kuhner direct drive which is very robust and provides accurate control of the orbital speed.

Scale-Up

Trouble free scale-up

The SB10-X fills a gap in the scale-up chain from commonly used single-use flasks all the way up to 50 L and 200 L bioreactors. The consistent hydrodynamics of shaken bioreactors provide reproducible cultivation conditions throughout the volume range. The culture from the SB10-X can serve as a preculture for the SB50-X and SB200-X OrbShakers. The SB10-X can also be used as a pilot scale bioreactor.

Online measurement

Heating and online pH & DO measurement

The tray module, which is fixed onto the ES-X shaker module, contains integrated heating and the connections for online pH and DO measurement.

Vessel module

Vessel module

Special emphasis has been placed on developing a user-friendly vessel module. The vessel together with its bag can be easily detached by the user and carried to the clean bench.

Filter heater

Filter heater

A filter heater for one exhaust filter is placed above the vessel module. The magnetic mounting makes handling the filter heater very simple and allows its location in various places. The filter heater combats water vapour condensation in the outlet air preventing blockages in the membrane

Control unit

Control unit and software

The compact and functional design of the control unit provides easy handling and monitoring of the bioprocess parameters. The control unit has an integrated and adjustable 12” touch screen with USB and Ethernet connections. The Kuhner Insight application software for data recording, calibration, programming and controlling is user-friendly and 21 CFR Part 11 compliant. Control of pH/DO, medium temperature, shaking frequency and gas flow rate and mixture is possible.

Pumping system

Pumping system

The control unit incorporates three peristaltic pumps which allow aseptic fluid management. This enables simple regulation of the pH-value, feeding and the transfer of the culture media (scale-up or processing).

Gas mixing

Gas mixing (FlowCon)

The SB10-X control unit has an integrated gas mixing device (FlowCon).

Whether stabilizing the pH with CO2, or preventing low dissolved oxygen concentrations, the gas mixer meets all user needs. Four mass flow controllers (N2, O2, CO2 and air or gas mixture) ensure highly accurate and reproducible gas mixing. An integrated pressure sensor prevents over pressure in the bioreactor. Step limits can be freely programmed by the user. Integrated air filters and back pressure valves ensure interference free and long operating times for the FlowCon.

Machine

| SB10-X | SMX7600 |

| Includes 6 module | – Shaker module ES-X – Control unit Bioreactor: – Tray module – Vessel module – Cable and tube management module – Filter heater |

Shaken Bioreactor

| Working volume | 4 L – 12 L |

| Total bag volume | approx. 24 L |

| Weight (bioreactor incl. shaker | approx. 75 kg without liquid |

| Required footprint (excl. control unit) | 669 mm x 646 mm |

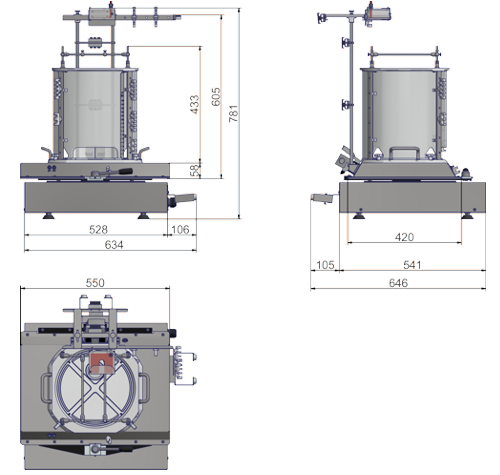

Dimensions (in mm) shaken bioreactor

Shaker module ES-X

|

Motor |

modified ES-X benchtop shaker |

|

Shaking diameter |

50 mm (orbital motion) |

|

Shaking speed |

20 rpm – 140 rpm |

|

Loading, maximum |

25 kg |

|

Setting, digital |

1 rpm |

|

Accuracy, absolute |

± 0.1 rpm |

|

Active brake |

adjustable |

|

Ambient temperature |

5°C – 40°C |

|

Casing |

stainless steel 1.4301 |

Mains connection

|

SMX1021: |

220 – 240 V / 50-60 Hz |

|

SMX1023: |

110 – 120 V / 50-60 Hz |

|

SMX1024: |

95 – 105 V / 50-60 Hz |

Temperature control

|

Heating |

resistance heater (100 W), |

|

Temperature max. |

40 °C |

|

Temperature min. |

approx. ambient temperature (no cooling) |

|

Temperature accuracy |

± 0.25 °C |

|

Temperature distribution |

8 mm thick aluminum plate provides homogenous temperature distribution

of resistance heater |

pH and DO control

|

pH measurement |

principle: optical chemosensor, |

|

Range |

pH 5.5 – pH 8.5 |

|

Accuracy (chemosensor) |

± pH 0.05 at pH 7 with one point calibration |

|

Drift |

< pH 0.005 per day |

|

Temperature range |

up to 50 °C |

|

|

|

|

DO measurement |

principle: optical chemosensor, |

|

Range |

0 % – 100 % DO |

|

Accuracy (chemosensor) |

± 0.1 % O2 at 20.9 % O |

|

Accuracy (system) |

± 10 % DO |

|

Drift |

< 0.015 % O2 per day |

|

Temperature range |

up to 50 °C |

Filter heater

|

Capacity |

1 exhaust filter |

|

Casing |

polycarbonate |

|

Heating |

resistance heater (6 W) |

|

Max. temperature |

approx. 40 °C at 23 °C ambient temperature |

|

Control |

orange LED light

indicates that filter heater is active and working |

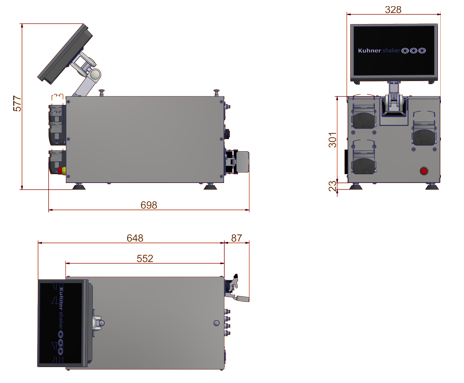

Control unit

|

|

(SMX76011) |

|

Weight |

approx. 30 kg |

|

Required footprint |

698 mm x 328 mm |

|

Casing |

Stainless steel 1.4301 |

|

Interface |

2 x CAN-Bus |

Dimensions (in mm)

Touch screen

|

Display |

12.1’’ screen (resistive) |

|

Resolution |

1024 x 768 |

|

Cooling |

passive with no fan |

|

Main memory |

2 GB (1.6 GB usable) |

|

Interfaces |

4 x USB, 2 x RS 232, 2 x LAN, 1 x VGA |

Software

|

|

Kuhner Insight application software |

|

Monitoring |

pH & DO, shaking

speed, temperature, gas flow and mixture, pressure |

|

Calibration |

pre-calibrated sensors in bag |

|

Recalibration |

one point recalibration is possible |

|

Applicable |

Win 7 & 10 |

|

GMP |

21 CFR Part 11 compliant |

Pumps

|

|

3 peristaltic pumps |

|

Type |

Watson-Marlow 313 VBM/D |

|

Rollers |

3 |

|

Power |

70 W |

|

Maximum Speed |

100 rpm |

|

Tube |

1.6 mm wall thickness |

|

Delivery Pressure |

max. 2bar |

|

|

|

|

Tube ID (mm) |

Flow rates (mL/min) at 100 rpm |

|

0.5 |

3.4 |

|

0.8 |

7 |

|

1.6 |

27 |

|

3.2 |

100 |

|

4.8 |

220 |

|

6.4 |

360 |

|

8 |

500 |

Gas mixing device (FlowCon)

|

Number of mass flow controllers |

4 |

|

Ambient conditions |

5 °C – 40 °C, max. 85 %rH |

|

Input |

up to 4 gases (air, oxygen, nitrogen, carbon dioxide) |

|

Output |

1 (tube fitting

optimal for tubing 9 x 1 mm)

air: 0.1 L min-1 – 1.99 L min-1

|

|

Pressure measurement |

gas output: pressure sensor DELOS SI (Jumo), |

|

Differential pressure |

0 mbar – 100 mbar (programmable) |

|

Gas filter |

integrated, prevents blocking of mass flow controllers |