SafeFAST Classic class II A1/A2 Microbiological Safety Cabinets belong to the latest generation of laminar airflow systems manufactured by Faster, in which the choice of materials of construction of the highest quality guarantees conformity to the strictest safety standards.

Faster SafeFAST Classic vertical laminar flow cabinets are Class II Microbiological Safety Cabinets – designed and built to performance requirements of the EN-12469:2000 European Standard and NSF/ANSI 49 American Standard, with 70% of the air re-circulated via the main H14 HEPA/ULPA filter according to EN 1822 within the cabinet, whilst the remaining 30% is discharged through an exhaust H14 HEPA/ULPA filter.

SafeFAST Classic have been adopted worldwide for product, personnel and environmental protection while handling harmful agents pathogenic to human beings and/or animals as defined in the appropriate international standards, in a wide range of applications such as: Microbiology, Virology, Hematology, Cell culture, Genetics, Handling of hazardous agents to human beings or animals.

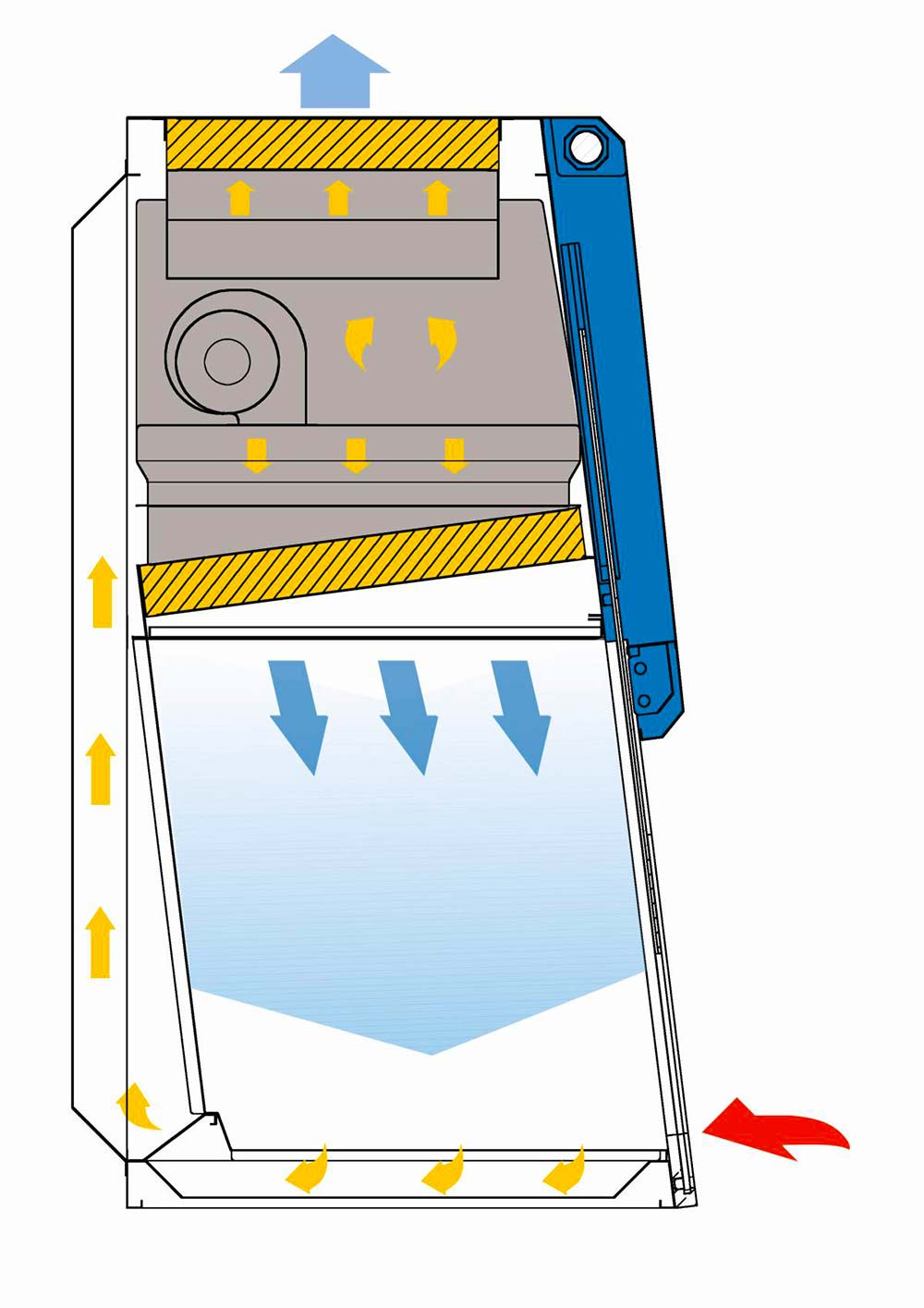

The ambient air is drawn in from the slots at the stainless-steel base of the front opening and it then passes under the work surface, from where it is drawn up and blown into the plenum of the re-circulating and exhaust fan(s).

The “bio-dynamic sealing system” of the negative pressure plenum ensures that all contaminated particles are kept inside the system and are automatically drawn to the plenum or pressure chamber to be captured by the main re-circulating and exhaust H 14 HEPA/ULPA filters.

The fan system assures that no part of the cabinet comes ever under positive contaminated pressure to the laboratory, thus protecting and preserving the environment and operating personnel from exposure to agents of bio-contamination.

70% of the filtered air is re-circulated (after passing through a H14 HEPA/ULPA filter) in an air cleanliness in Class ISO 3, according to ISO 14644-1 laminar flow pattern downwards into the work chamber and the remaining 30% is exhausted to atmosphere through another H14 HEPA/ULPA filter.

Ergonomic Design: The angled sloping (7°) front stratified safety-glass sash provides optimum visibility of all objects placed in the interior workspace. The sash is electrically operated. Pressing the appropriate touch-sensitive keys will completely open or completely close down the sash. The standard sash-height opening during work is set to 200 mm. Alternative sash-height settings by the factory are possible upon request. The whole front of the safety cabinet – which includes the sash mechanism – can also be opened upwards as it is hinged on the top – in order to allow easy access for complete and effective cleaning and decontamination.

Real Laminar AirFlow: Frontal screen 7° sloped as well as back side wall to convey in unidirectional pattern the air flow. As a consequence, the front and back panels are parallel one with the other and there is the real presence of Laminar AirFlow in the whole working area.

ECS® Eco Controling System: The new ECS® microprocessor employs the latest innovative methods of integrated management of all principal functions of ventilation and filtration – self-regulating all the main filtration and ventilation system components – compensating for declining pressure drops and restoring power balance. Combining the use of AC motor-blowers and certified low pressure-drop filters, the new ECS® controlling system optimize power consumption, reducing CO2 emissions into the environment.

Anti Bacterial Coating: Exclusive Dupont™ ALESTA® anti-bacterial “Ag+ cations-based solution”, capable to prevent microbial contamination of surfaces thereby inhibiting long term surface growth.

Silent Operation: The TNT plenum, the structures of the electric motors of the fans fitted on their antivibration mounts and the software itself designed to provide optimum air handling characteristics guarantee quiet operation of this silent safety cabinet, with sound-pressure levels recorded way below the parameters specified in the current EN:12469 European Standard for Microbiological Safety Cabinets.

High Level Lighting: The safety glass side-windows with the ideal positioning and sizing of the light-system provide the highest level of luminosity to the work area.

Easy handling and maintenance: The cabinet can pass through standard 800 mm wide door openings. In fact, the overall depth of the cabinet can be reduced TO

Electrical sockets fitted as standard in each size model: one

External structure in epoxy powder coated cold-rolled steel for excellent corrosion resistance to the attack by aggressive common chemicals. Alternatively special models with external structure made in AISI 304L stainless steel for superior cleanability are also available on demand.

Rear wall in epoxy coated steel, designed to conform to requirements and pass the “cleanability test” according to EN12469:2000.

Work surface in AISI 304L consisting of sections (or in one piece upon request) which are easily removable for carrying out routine cleaning and/or autoclaving sterilization procedures; closed or perforated on request.

Front window: electrically operated vertically sliding safety glass sash window.

Re-circulating and extractor fan: SafeFAST Classic are supplied with single centrifugal fan.

Servicing side glass with ports for service taps installation.

Filtration: H14 HEPA/ULPA filters with an efficiency better than 99,995 % MPPS (EN-1822).

Operation Condition: Air cleanliness in Class ISO 3 as per ISO:EN 14644-1.

The user-friendly practical keyboard and the rear-lit LCD will continuously display all required data keeping the user constantly informed of the cabinet conditions in operation, and in particular:

- display of laminar airflow velocity and frontal air barrier velocity

- display of inside and outside temperature

- display of residual lifetime of HEPA/ULPA filters, UV Lamp and activated carbon filter (if fitted)

- display of total number of hours of operation

- display of saturation level of HEPA/ULPA filters.

Audio-visual alarms provided for:

- out of range or incorrect laminar airflow velocity and frontal air barrier velocity

- incorrect position of front sash-window

- clogging of HEPA/ULPA filters

- end of life-cycle of UV lamp and saturation of activated carbon filter (if fitted)

- blockage in the exhaust duct ( if fitted )

- fan-motor malfunction

- power failure

Magnetic and removable UV sterilizing lamp (optional) that can be easily placed in each area of the back wall. It is completed with two switch-off countdown timers, one variable on a 0-3 hours scale (1 minute steps), the other set to 3 fixed hours.

Lighting: fluorescent tubes in built-in housing, placed outside the contaminated are

D.O.P.- DEHS inlet port for testing the HEPA/ULPA filters

| Code | F00001110000 |

| Width [cm] | 90 |

| Motor-blowers | Single fan |

| Pressure | Negative |

| Technical sheet | |

| Useful dimension (mm) WxDxH | 887x580x740 |

| Overall dimension [mm] WxDxH | 1045x810x1545 (*) |

| Noise level (dbA) | 53 |

| Working Aperture (mm) | 200 |

| Exhaust flow rate (m3/h) | 290 |

| Lighting level (lux) | >1100 |

| Weight (kg) | 170 |

| Electrical data [230V – 50H] (**) | 230 V – 50 Hz |

| Current consumption (A) | 1,9 |

| Heat emission (W) | 175 |

| (*) overall depth can be reduced to : (**) different voltage/frequency available upon request |