The All-Rounder for Data Acquisition

Whether it is calibration, material, or fatigue testing, the MGCplus data acquisition system is used in all kinds of applications. It acquires data on strain, force, displacement, torque, voltage, current, temperature, and many other parameters. Owing to this versatility, the MGCplus is one of the most popular data acquisition systems worldwide. It offers proven compatibility, not only within the MGCplus system but also along the entire measurement chain from the sensor to the software.

Reliable

- Over 25 years of experience in service and support

- DC amplifiers for high dynamics and carrier frequencies for highest accuracy

- Integrated automatic calibration (AutoCal) ensures long-term stability

Upgradable

- Modular system design that meets a wide range of requirements

- Number of channels can be expanded from 1 to 20,000

- Stand-alone USB data storage

Versatile

- Single and multiple channel amplifiers for almost all physical quantities

- Display and control panel for operation without software

- Simultaneous and parallel measurement using three independent sampling rates

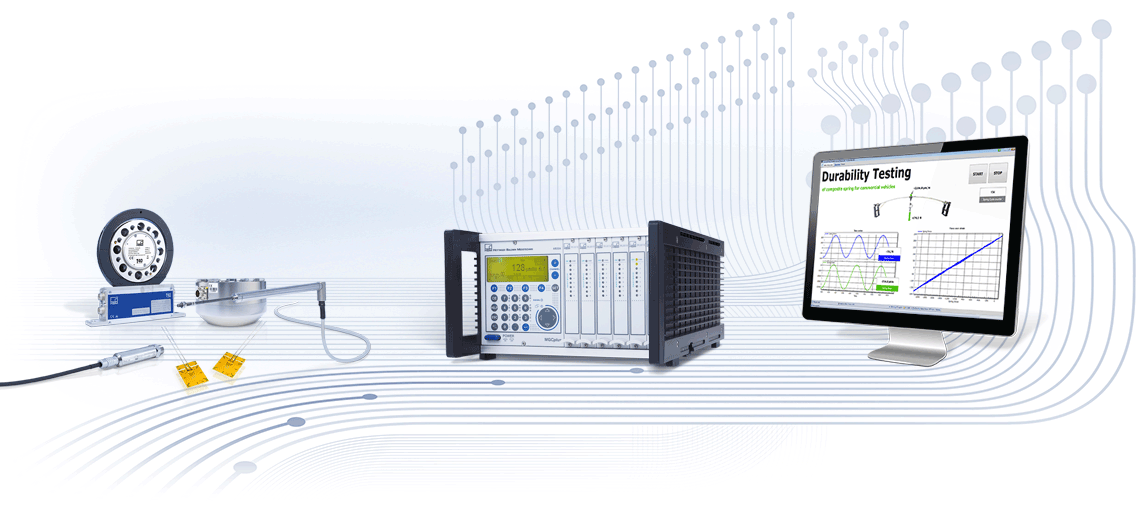

Measurement Chains for all Channel Counts

MGCplus, together with HBM’s precise sensors and transducers and the data acquisition software catman, forms a reliable measurement chain which can be scaled up to 20,000 channels.

Focus Applications

Lab and Bench Testing

Lab and Bench Testing

Aerospace Testing

Aerospace Testing

- Structural testing (static and durability)

- Wind tunnel testing

- Center of gravity analysis

System Components

MGCplus is modular, thus it offers maximum flexibility. In just a few easy steps, MGCplus can be adapted to the specific task. Every system consists of the following components:

- Desktop housing or rack frame

- Communication processor

- Measuring amplifiers

- Connection boards

For more information about this product click here.