PT Wadya Prima Mulia as the Authorized Distributor for ThermoFisher Scientific in Indonesia, provides Phenom PrticleX Desktop Scanning Electron Microscope

Desktop SEM for additive manufacturing analysis, capable of observing large samples up to 100 mm x 100 mm.

For more information regarding the product, click here

Additive manufacturing analysis

The Thermo Scientific Phenom ParticleX Desktop Scanning Electron Microscope (SEM) is a multi-purpose desktop SEM designed for additive manufacturing, delivering purity at the microscale.

It is equipped with a chamber large enough to analyze samples up to 100 mm x 100 mm. The proprietary venting and loading mechanism ensures the fastest vent/load cycle in the world, providing the highest throughput.

With the Phenom ParticleX AM Desktop SEM, you can take in-house control of your data:

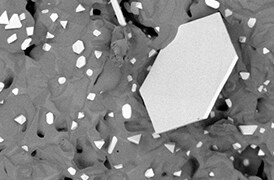

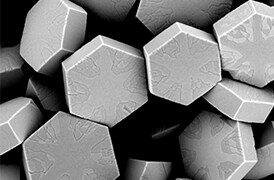

- Monitor critical characteristics of metal powders

- Enhance your powder-bed and powder-fed additive manufacturing processes

- Identify particle size distributions, individual particle morphology, and foreign particles

SEM particle analysis

The Phenom ParticleX AM Desktop SEM features a chamber with an accurate and fast motorized stage that allows analysis of samples of up to 100 mm x 100 mm. Even with this larger sample size, the proprietary loading shuttle keeps the vent/load cycle to an industry-leading loading time of 60 seconds or less, ultimately delivering faster throughput than other SEM systems.

SEM elemental mapping

The elemental mapping and line scan functionality lets you start working with a single click. The line scan functionality shows the quantified element distribution in a line plot. This is especially useful for analyzing edges, coatings, and cross sections of coatings, paints, and other samples with multiple layers.

Additive manufacturing testing

The Phenom ParticleX AM Desktop SEM measures various size and shape parameters, such as minimum and maximum diameter, perimeter, aspect ratio, roughness, and feret diameter. All of these can be displayed with 10%, 50%, or 90% values (i.e., d10, d50, d90).

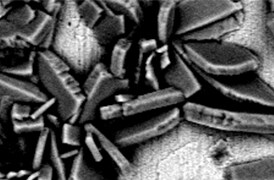

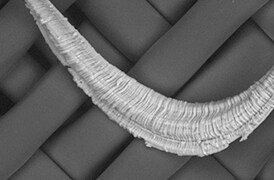

Secondary electron detector

An optional secondary electron detector (SED) can be added to the Phenom ParticleX AM Desktop SEM. The SED collects low-energy electrons from the top surface layer of the sample, making it ideally suited to revealing detailed sample surface information. The SED can be of great use for studying microstructures, fibers, and particles or other applications where topography and morphology are important.

| Electron optical | • Long lifetime thermionic source (CeB6 ) • Multiple beam currents |

| Electron optical magnification range | 160 – 200,000x |

| Light optical magnification | 3–16x |

| Resolution | <10 nm |

| Image resolution options | 960 x 600, 1920 x 1200, 3840 x 2400 and 7680 x 4800 pixels |

| Acceleration voltages | • Default: 5 kV, 10 kV and 15 kV • Advanced mode: adjustable range between 4.8 kV and 20.5 kV imaging and analysis mode |

| Vacuum levels | Low – medium – high |

| Detector | • Energy dispersive X-ray spectroscopy (EDS) detector (standard) • Secondary electron detector (optional) |

| Sample size | • Max. 100 mm x 100 mm (up to 36 x 12 mm pin stubs) • Max. 40 mm (h) |

| Sample loading time | • Light optical <5 s • Electron optical <60 s |

Process control using electron microscopy

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

More than ever, modern manufacturing necessitates reliable, quality components. With scanning electron microscopy, parts cleanliness analysis can be brought inhouse, providing you with a broad range of analytical data and shortening your production cycle.

For other products from ThermoFisher, click here.