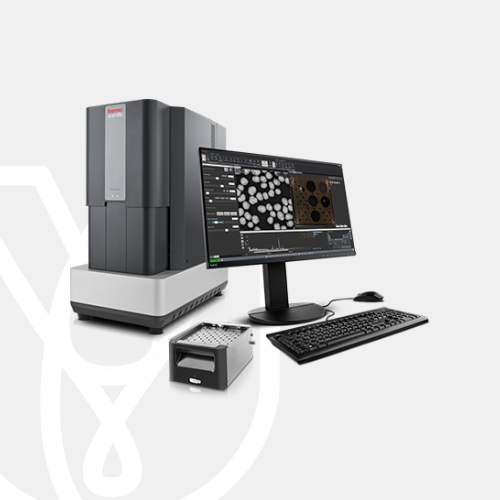

PT Wadya Prima Mulia as the Authorized Distributor for ThermoFisher Scientific in Indonesia, provides Phenom ParticleX Battery Desktop SEM Scanning Electron Microscope

Desktop scanning electron microscope for battery production and research.

For more information regarding the product, click here

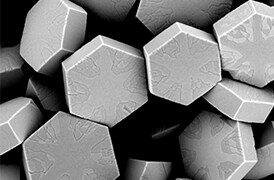

Advanced battery materials analysis

Phenom Desktop SEM designed for battery materials analysis

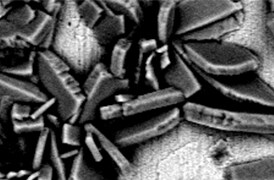

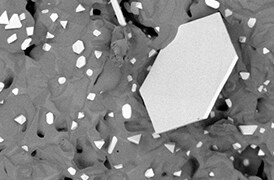

In battery production and research, the quality of materials is becoming critical. Small contaminants in the NCM powder, for example, can have disastrous results in the final product. To trace these contaminants effectively, high-resolution SEM imaging with EDS analysis for chemistry is needed. When fully automated, this combination is a powerful tool for powder quality inspection.

Conductance classifications

Each particle class can be labeled with a conductance of the particles, allowing you to sort on conductance of particles. This allows you to assess the impact of contamination much more accurately since a small organic contamination is not as severe as a metallic conductive contamination.

Ternary diagram

To view overall chemistry of the particle population, a ternary diagram can be generated where all particles are represented. With Ni, Co, and Mn on each axis, the outyears and general trends can be seen instantly.

| Electron optical | • Long lifetime thermionic source (CeB6 ) • Multiple beam currents |

| Electron optical magnification range | 160 – 200,000x |

| Light optical magnification | 3 to 16x |

| Resolution | <10 nm |

| Image resolution options | 960 x 600, 1920 x 1200, 3840 x 2400 and 7680 x 4800 pixels |

| Acceleration voltages | • Default: 5 kV, 10 kV and 15 kV • Advanced mode: adjustable range between 4.8 kV and 20.5 kV imaging and analysis mode |

| Vacuum levels | Low – medium – high |

| Detector | • Backscattered electron detector (standard) • Energy-dispersive X-ray spectroscopy (EDS) detector (standard) • Secondary electron detector (optional) |

| Sample size | • Max. 100 mm x 100 mm (up to 36 x 12 mm pin stubs) • Max. 40 mm (h) |

| Sample loading time | • Light optical <5 s tubs) • Electron optical <60 s |

Process control using electron microscopy

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

For other products from ThermoFisher, click here.