X-ray photoelectron spectroscopy

The Thermo Scientific Nexsa G2 X-Ray Photoelectron Spectrometer (XPS) System offers fully automated, high-throughput surface analysis, delivering the data to advance research and development or to solve production problems. The integration of XPS with ion scattering spectroscopy (ISS), UV photoelectron spectroscopy (UPS), reflected electron energy loss spectroscopy (REELS), and Raman spectroscopy, allows you to conduct true correlative analysis. The system now includes options for sample heating and sample biasing capabilities to increase the range of experiments now possible. The Nexsa G2 Surface Analysis System unlocks the potential for advances in materials science, microelectronics, nanotechnology development, and many other applications.

High-performance X-ray source

The X-ray monochromator allows selection of analysis area from 50 µm to 400 µm in 5 µm steps, fitting it to the feature of interest to maximize the signal.

Optimized electron optics

The high-efficiency electron lens, hemispherical analyzer, and detector allow for superb detectability and rapid data acquisition.

Sample viewing

Bring sample features into focus with the K-Alpha XPS System’s patented optical viewing system and XPS SnapMap, which helps you pinpoint areas of interest quickly.

Insulator analysis

The patented dual-beam flood source couples low-energy ion beams with very low energy electrons (less than 1 eV) to prevent sample charging during analysis, which eliminates the need, in most cases, for charge referencing.

Depth profiling

Go beyond the surface with the EX06 ion source. Automated source optimization and gas handling ensure excellent performance and experimental reproducibility.

Digital Control

Intuitive operation—guided by the Avantage data system—makes the K-Alpha XPS System ideal for both multi-user, shared facilities and XPS experts who place a premium on efficient operation and high-throughput analysis.

Optional sample holders

Specialist sample holders for angle-resolved XPS, sample bias measurements, or for inert transfer from a glove box are available.

NX sample heater module

Fully software-controlled sample heating option, enabling temperature-dependent studies.

| Analyzer type | 180°, double-focusing, hemispherical analyzer with 128-channel detector |

| X-ray source type | Monochromated, micro-focused, low-power Al K-Alpha X-ray source |

| X-ray spot size | 10–400 µm (adjustable in 5 µm steps) |

| Depth profiling | EX06 monatomic ion source or MAGCIS dual-mode ion source |

| Maximum Sample area | 60 x 60 mm |

| Maximum sample thickness | 20 mm |

| Vacuum system | Two turbo molecular pumps, with automated titanium sublimation pump and backing pump |

| Optional accessories | UPS, ISS, REELS, iXR Raman spectrometer, MAGCIS, sample tilt module, NX sample heating module, sample bias module, vacuum transfer module, adaptor for glove box integration |

Battery development is enabled by multi-scale analysis with microCT, SEM and TEM, Raman spectroscopy, XPS, and digital 3D visualization and analysis. Learn how this approach provides the structural and chemical information needed to build better batteries.

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Polymer microstructure dictates the material’s bulk characteristics and performance. Electron microscopy enables comprehensive microscale analysis of polymer morphology and composition for R&D and quality control applications.

Geoscience relies on consistent and accurate multi-scale observation of features within rock samples. SEM-EDS, combined with automation software, enables direct, large-scale analysis of texture and mineral composition for petrology and mineralogy research.

As the demand for oil and gas continues, there is an ongoing need for efficient and effective extraction of hydrocarbons. Thermo Fisher Scientific offers a range of microscopy and spectroscopy solutions for a variety of petroleum science applications.

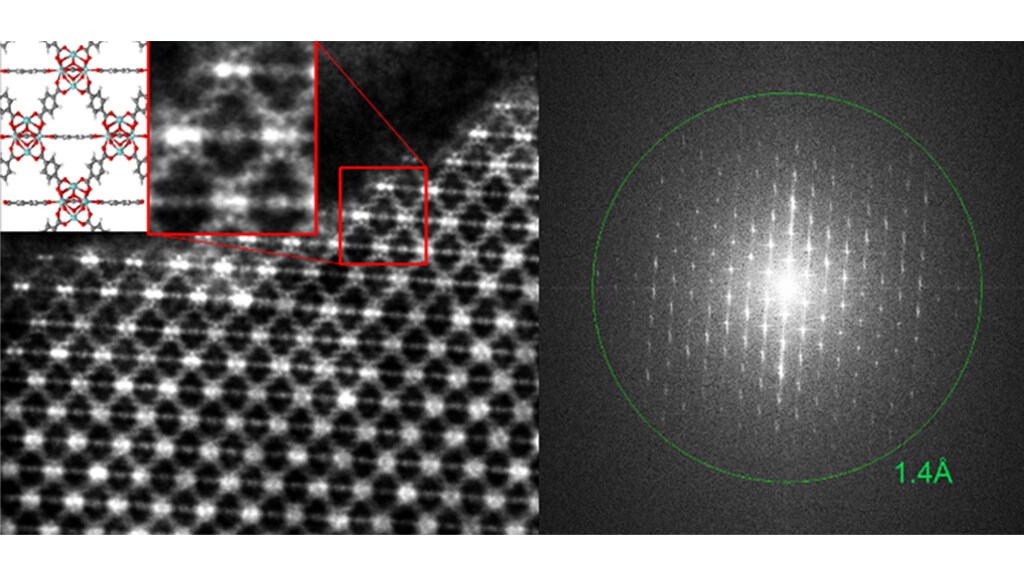

Materials have fundamentally different properties at the nanoscale than at the macroscale. To study them, S/TEM instrumentation can be combined with energy dispersive X-ray spectroscopy to obtain nanometer, or even sub-nanometer, resolution data.

Micro-traces of crime scene evidence can be analyzed and compared using electron microscopy as part of a forensic investigation. Compatible samples include glass and paint fragments, tool marks, drugs, explosives, and GSR (gunshot residue).

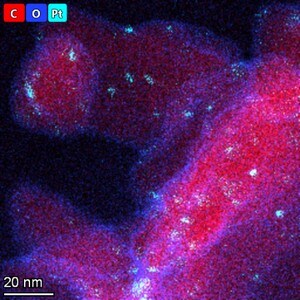

Catalysts are critical for a majority of modern industrial processes. Their efficiency depends on the microscopic composition and morphology of the catalytic particles; EM with EDS is ideally suited for studying these properties.

The diameter, morphology and density of synthetic fibers are key parameters that determine the lifetime and functionality of a filter. Scanning electron microscopy (SEM) is the ideal technique for quickly and easily investigating these features.

Novel materials research is increasingly interested in the structure of low-dimensional materials. Scanning transmission electron microscopy with probe correction and monochromation allows for high-resolution two-dimensional materials imaging.

Every component in a modern vehicle is designed for safety, efficiency, and performance. Detailed characterization of automotive materials with electron microscopy and spectroscopy informs critical process decisions, product improvements, and new materials.

For other products from ThermoFisher, click here.